What workshops need to know to diagnose ADAS issues accurately and efficiently

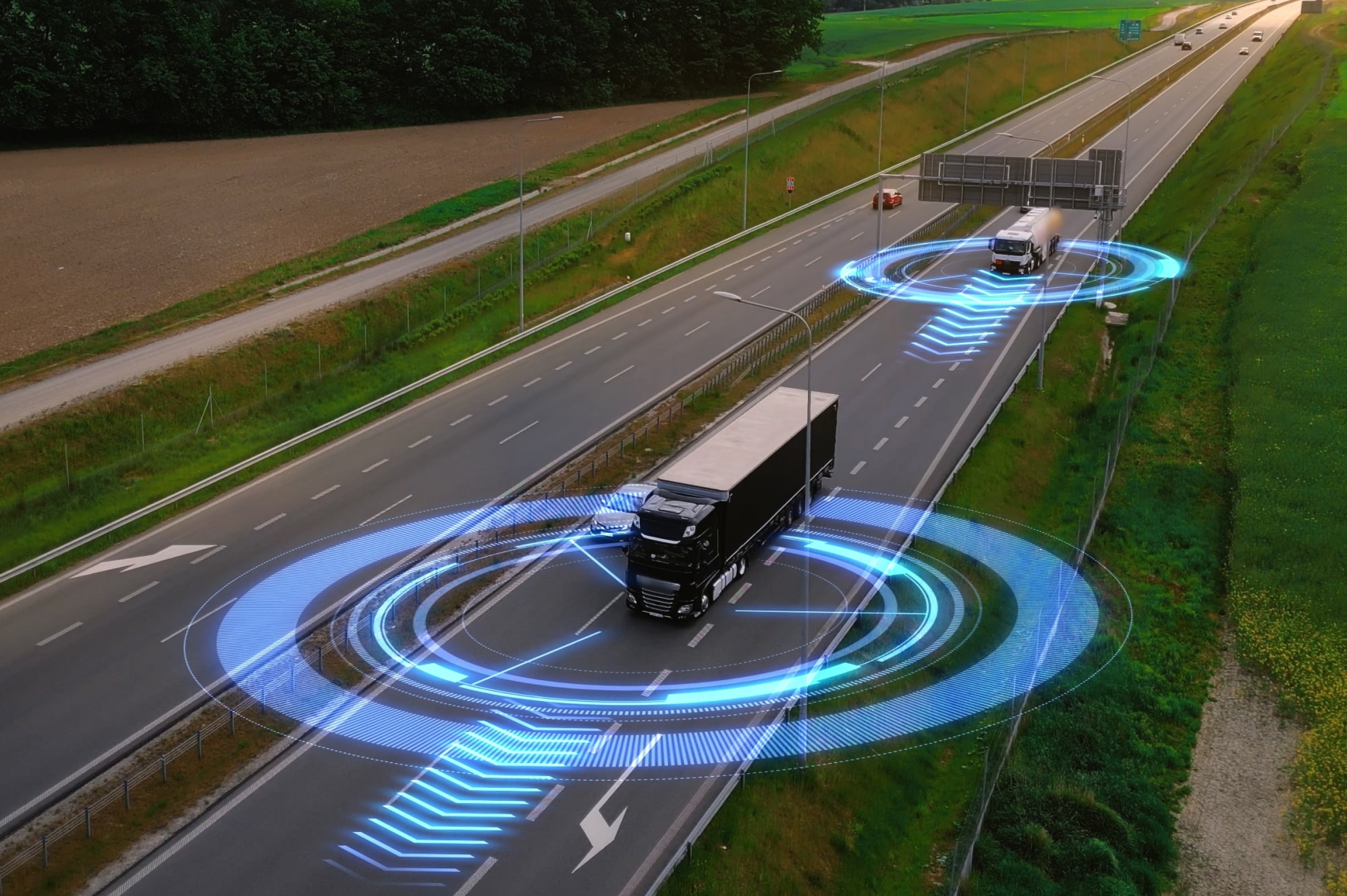

Advanced Driver Assistance Systems (ADAS) are no longer limited to high-end passenger cars. They are now a standard feature across many modern commercial vehicles, buses, coaches, agricultural machines and off-highway equipment.

Advanced Driver Assistance Systems (ADAS) are no longer limited to high-end passenger cars. They are now a standard feature across many modern commercial vehicles, buses, coaches, agricultural machines and off-highway equipment.

Systems such as adaptive cruise control, lane departure warning, automatic emergency braking and blind-spot monitoring are designed to improve safety, reduce accidents and support drivers in increasingly complex driving environments.

However, as ADAS technology becomes more widespread, workshops are seeing a sharp rise in ADAS-related faults. These faults are not always obvious, they do not always trigger warning lights, and they can be time-consuming to diagnose without the right approach and equipment.

In many cases, an incorrectly diagnosed ADAS fault can lead to repeated vehicle returns, unhappy customers and potential safety risks.

In this article, we explore the most common ADAS sensor faults workshops encounter and, more importantly, the diagnostic strategies that help technicians identify and resolve these issues efficiently and accurately.

Understanding ADAS Sensors and Why Faults Occur

ADAS relies on a network of sensors that constantly monitor the vehicle’s surroundings. These typically include cameras, radar sensors, ultrasonic sensors and, in some applications, LiDAR. Each sensor has a specific role, and the system works by combining data from multiple sources to make real-time decisions.

Because ADAS sensors are externally mounted and operate in challenging environments, they are particularly vulnerable to faults. Dirt, weather exposure, vibration, impact damage and even minor bodywork repairs can all affect sensor performance. Unlike traditional mechanical faults, ADAS issues are often related to alignment, calibration or signal quality rather than complete component failure.

This is why a structured diagnostic strategy is essential. Simply replacing a sensor rarely solves the problem and can introduce new issues if calibration is not carried out correctly.

Camera-Based ADAS Faults

Forward-facing cameras are at the heart of many ADAS functions, including lane keeping assist, traffic sign recognition and forward collision warning. These cameras are usually mounted behind the windscreen or within the front grille area.

One of the most common camera-related faults is misalignment. Even a small change in camera angle can cause the system to misinterpret lane markings or distance to other vehicles. Windscreen replacement is a frequent trigger for this type of fault, particularly if calibration is skipped or performed incorrectly.

Camera obstruction is another regular issue. Dirt, condensation, ice or even poorly positioned stickers can interfere with the camera’s field of view. In some cases, the system may still function but with reduced accuracy, making faults harder to identify.

From a diagnostic perspective, technicians should always begin with a visual inspection before connecting a diagnostic tool. Checking for physical obstructions, damage or signs of movement can often reveal the root cause quickly. Once the physical checks are complete, a diagnostic scan can confirm fault codes and identify whether static or dynamic calibration is required.

Radar Sensor Issues and False Alerts

Radar sensors are commonly used for adaptive cruise control, blind-spot detection and collision avoidance. They are typically mounted behind bumpers or within the vehicle’s front and rear panels, making them particularly sensitive to bodywork changes.

A frequent problem with radar-based ADAS is incorrect sensor alignment following minor accidents or bumper repairs. Even small impacts that do not leave visible damage can shift a radar sensor just enough to trigger false alerts or disable the system entirely.

Another common issue is interference caused by non-original paint thickness, metallic paint finishes or poorly fitted accessories. These can alter the radar signal and lead to inconsistent system behaviour.

Effective diagnosis requires more than reading fault codes. While a diagnostic tool can identify communication or internal sensor faults, calibration status is equally important. Many radar issues only become apparent when live data is analysed, highlighting the importance of diagnostic tools that support real-time sensor monitoring and guided calibration procedures.

Ultrasonic Sensor Problems in Parking and Low-Speed Systems

Ultrasonic sensors are widely used for parking assistance and low-speed manoeuvring. Although they are relatively simple compared to cameras and radar, they still generate a high volume of workshop complaints.

The most common ultrasonic sensor faults are contamination and physical damage. Mud, road salt and debris can block the sensor surface, while minor knocks can crack the housing without being immediately obvious.

Because ultrasonic systems operate at low speeds, drivers often assume faults are minor. However, inconsistent warnings or complete system failure can indicate wiring issues, sensor degradation or control unit problems.

A good diagnostic strategy involves checking sensor operation individually rather than relying on system-wide fault codes. Many diagnostic platforms allow technicians to trigger sensors manually and listen for activation, helping to pinpoint the faulty component quickly.

Calibration Errors After Repairs

One of the most overlooked causes of ADAS faults is missed or incorrect calibration after routine repairs. Wheel alignment, suspension work, tyre replacement and body repairs can all affect ADAS sensor positioning.

In many cases, the vehicle may not immediately display a fault warning, but ADAS functions will be disabled or operate incorrectly. This can lead to dangerous situations, particularly in commercial vehicles where drivers rely heavily on assistance systems during long shifts.

Workshops should treat ADAS calibration as a standard step in post-repair procedures. Diagnostic tools that provide clear calibration instructions, vehicle-specific targets and guided workflows are essential for ensuring accuracy and consistency.

Diagnostic Strategies for Accurate ADAS Fault Finding

Successful ADAS diagnostics require a methodical approach that combines physical inspection, diagnostic scanning and calibration verification. Relying on fault codes alone is rarely sufficient, as many ADAS issues relate to sensor positioning or environmental factors rather than electrical failure.

A structured diagnostic process should include:

- A thorough visual inspection of sensors, mounting points and surrounding areas

- A full system scan to identify stored and pending fault codes

- Review of live data to assess sensor performance

- Verification of calibration status and completion of recalibration where required

This approach not only improves diagnostic accuracy but also reduces unnecessary part replacement and repeat visits.

The Role of Advanced Diagnostic Tools in ADAS

Modern ADAS diagnostics demand more than basic fault-code readers. Workshops need tools that support advanced calibration procedures, live data analysis and guided diagnostic functions across multiple vehicle types.

Modern ADAS diagnostics demand more than basic fault-code readers. Workshops need tools that support advanced calibration procedures, live data analysis and guided diagnostic functions across multiple vehicle types.

Multi-brand diagnostic platforms with ADAS coverage allow technicians to work confidently on a wide range of vehicles without relying on manufacturer-specific equipment. This is particularly important for independent workshops and fleet maintenance providers managing mixed vehicle fleets.

Training is equally important. Even the best diagnostic tool cannot compensate for a lack of understanding of how ADAS systems operate. Investing in ongoing technician education helps ensure that diagnostic capabilities keep pace with rapidly evolving vehicle technology.

Why Accurate ADAS Diagnostics Matter

ADAS faults are not just technical issues; they are safety-critical concerns. Incorrectly diagnosed or unresolved ADAS problems can compromise driver safety, increase liability risks and damage customer trust.

For workshops, getting ADAS diagnostics right offers a significant opportunity. As vehicles become more technologically complex, workshops that can confidently diagnose and calibrate ADAS systems will stand out in an increasingly competitive market.

By adopting a structured diagnostic strategy, using the right tools and prioritising calibration accuracy, workshops can turn ADAS complexity into a clear competitive advantage.

Jaltest ADAS Calibration Equipment

In addition to understanding common sensor faults, having the right calibration tools is essential for accurate ADAS diagnostics and repair.

The Jaltest ADAS calibration equipment, available through Eclipse, is designed specifically to support workshops in performing comprehensive static and dynamic calibration on a wide range of commercial vehicles, including trucks, buses, coaches and light commercial vehicles.

This multi-brand solution enables technicians to calibrate systems such as adaptive cruise control, lane departure warning, forward collision warning and advanced emergency braking with step-by-step procedures, live data access, interactive wiring diagrams and detailed technical information integrated into the workflow.

With coverage across hundreds of models and a modular, easy-to-set-up frame with self-centring tools and multi-brand targets, Jaltest ADAS helps ensure that sensors and cameras are aligned to manufacturer specifications — reducing guesswork and improving confidence in calibration results.

Final Thoughts

ADAS systems are here to stay, and the volume of ADAS-related diagnostic work will only increase. Understanding common sensor faults and applying proven diagnostic strategies is essential for any workshop working on modern vehicles.

From camera misalignment to radar interference and calibration errors, most ADAS faults can be resolved efficiently with the right knowledge and equipment. By focusing on accuracy rather than speed, workshops can deliver safer repairs, reduce comebacks and build long-term customer confidence.

As ADAS technology continues to evolve, staying informed and prepared is no longer optional. It is a key part of modern vehicle diagnostics and a vital skill for the future of the workshop.